Shanghai Salvage Company(SSC), also known as China Ocean Engineering Solutions Limited (COES) established its salvage business in 1951 with responsibilities for people rescue, recovery of marine property, wreck removal, spilled-oil recovery and other emergency responses for the southeastern coastal area of China. SSC is a leading salvage company in China and its “Shanghai Salvage” brand-name has already become world-famous and globally recognized. The company has received international acclaim for successfully completed some of the world most complex and challenging salvage projects.

SSC hires highly-experienced salvage masters, specialized vessels and equipment, and all kinds of emergency materials and supplies promptly available to provide rescue services, marine wreck removal, environmental protection and clean-up, and property salvage… on a 24/7 basis.

Over the years, we have salvaged more than 2000 vessels in distress of all sorts, removed more than 1900 wrecks, cleared over 29,000 tons spilled-oil. Recent years worldwide famous wreck removing projects including: 1) Wreck Removal for sunken “SEWOL” in Korea, 2015 – 2017. 2) KEA TRADER wreck removal in New Caledonia, South Pacific, 2018-2021 3) X-Press Pearl wreck removal in Sri Lanka, 2022-ongoing.

SEWOL Wreck Removal

Korea Ro-Ro vessel SEWOL sank in April 2014. The Wreck Site is near Jindo Coast, South Korea. The water depth at the wreck site is about 44m. The vessel is lying on the seabed with a 90-degree heel on portside. Over 300 lives were lost in the sinking with perhaps 9 missing victims’ bodies possibly remaining in the wreckage. The consortium of SSC and a local salvage company won the contract for the recovery of the SEWOL hull and its missing victims. The salvage operation began in August, 2015. To fulfill the Korean authority’s requirement, SSC has provided specialized equipment and vessels in addition to a large team of highly professional and experienced personnel to successfully complete the Project. The workscope for the SEWOL salvage operation includes pre-survey, remaining oil recovery, hull recovery and hull transportation. To prevent the loss of missing victims, soft steel wire meshes were installed as safety nets on the outside windows, doors and broken hatches. Every measure was taken to ensure the recovery of SEWOL in one piece and to minimize further hull damage.

KEA TRADER Wreck Removal

The 2,194-TEU capacity container vessel, KEA TRADER, ran aground on Durand Reef, in the French territory of New Caledonia in the South Pacific Ocean, on 12th July 2017, whilst enroute from Papeete (Tahiti, French Polynesia) to Noumea, New Caledonia. The hull of Kea Trader has been continuously damaged over the past grounded period and completely broken into two parts in the middle of November 2017 during a prolonged period of severe weather. And the condition of the hull of Kea Trader has been continuously getting deteriorated with the changing of position and posture of the forward and aft sections after going through long time of severe swell and several cyclones. Shanghai Salvage Company was awarded the contract to remove the vessel on 3rd March, 2018. As water depth is only between 7~10m, a specifically modified crane barge with aground capacity was engaged to successfully complete the removal of the wreck. The crane barge is maneuvered and positioned close to the shipwreck with eight points spread mooring system.

“Sanchi” salvage

The “Sanchi” salvage project was a further example of complex project success for the Company. In January 2018, the Belize flag oil tanker "Sanchi" and the Hong Kong flag bulk carrier "Changfeng Crystal" collided, resulting the "Sanchi" in a catastrophic fire. The ship had been fully loaded with condensate oil (about 113,000 tons) and with 32 people onboard had been lost. Shanghai Salvage / COES immediately mobilized and dispatched nearly 130 workers and 4 emergency firefighting vessels dedicated to the effort. Additionally, as a matter of urgency, nearly 450 tons of firefighting foam and emergency equipment in East China were mobilized to offshore site. Working in the most dangerous of circumstances - the ship was approached for firefighting for many continuous days with careful consideration given as to the fire blast risk on a vessel carrying such dangerous cargo.

On January 13th, a team of 4 company specialists embarked on a hazardous (but risk assessed mission). They resolutely boarded the blasting “Sanchi” and successfully retrieved the ship’s VDR equipment. They also located and brought back the remains of two of the ships’ crew members, confirming that there were no further survivors. This was important as a basis for subsequent follow-up investigations, but nonetheless highlighted a determined relentless spirit of international humanitarianism.

Wreck Removal of M/V “Bareli”

In March 2012, the container ship “Bareli” was stranded in the Xinghua Bay area and later inclined and broke apart. The unfortunate vessel was laden with 2000 tons of chemicals. SSC promptly dispatched our 2500T crane barge “Da Li Hao” to the site, complete with pumping and oil-recovery equipment and a specialized team as requested by Client. SSC first offloaded the containers on board and removed the bunker oil to minimize risk of property damage and environment pollution. Upon discharging, the aft part of broken wreck was cut and towed to a safe place. Later, the fore part was exploded and the wreckage was cleared. The whole project was completed in 131 days. With continuous and hard work, 819.4 cubic meters of bunker oil were removed and 1233 containers were offloaded. SSC was highly praised by Client for the efficient and successful operation.

Salvage for container “Rickmers Genoa”

In March 2005, the multi-purpose container ship Rickmers Genoa collided with the Korean registered Sun Cross off Lianyungang, China. As a result of the collision, Sun Cross sank while Rickmers Genoa sustained significant structural damage. Her forward section incurred flooding in the No. 1 Hold causing a number of powerful explosions therein and resulting in further structural damage with severe fire and thick, black toxic-smoke. SSC promptly dispatched the salvage tugs Hua Ji, Hua Xiang and other salvage vessels, including the 2500T crane barge Da Li Hao. During the salvage services, SSC’ highly-experienced salvage master and salvage team made every effort to extinguish the fire, to prevent further explosions, to prevent pollution to ocean environment, to ensure the safety of the crews’ lives and to prevent the loss of the cargo and the vessel. The salvage operation was successful and after about 50 days’ hard and fruitful work, the casualty and her cargo was smoothly delivered to her owner. SSC’s professional and successful operation was highly appreciated by the Client.

Salvage of M/V “CMA CGM LIBRA”

The container ship “CMA CGM LIBRA” sailed from Xiamen but thereafter ran aground near the Jiu Jie Reef. She is a third-generation container ship with an overall length of 363.61 meters, a beam of 45.66 meters, and weighing 131,332 gross tonnes. The ship-owner initially engaged five local harbour tugs in order to refloat the vessel. This effort was unsuccessful, therefore the ship-owner then hired SSC to conduct the salvage under the terms of LOF 2011. SSC promptly dispatched the heavy-lift crane barge “DA LI HAO” and other equipment/vessels to the site to conduct the salvage operation. Once on location, SSC began a series of activities to lighten the ship, including the transfer and de-loading of oil, which ultimately resulted in the refloating of the ship and its cargo. At the time, CMA GGM LIBRA was the largest ship that ever grounded along the Chinese coast. The quick response and the skilled refloating of this ship further substantiates SSC’s lengthy track record for professionalism and efficiency in conducting emergency rescue and salvage activities.

Salvage of M/V “CCNI RIMAC”

On 21st June, 2011, the container ship “MV CCNI RIMAC” was seriously damaged during a collision in Yangshan Port. Six layers of containers stacked onboard the ship’s deck were severely compromised or destroyed and causing instability to the ship. Additionally, the fifth cargo hold contained 72 tons of dangerous chemicals requiring immediate removal to prevent the risks of explosion and /or harm to the environment. Shanghai’s municipal government was fully concerned about the incident and the risks of further harm to people and the environment. Per government requirements, SSC promptly initiated a contingency plan for the overall salvage process, and thereafter safely transferred the worrisome container cargos and hazardous chemicals prior to the approaching typhoon MILEI. Thereafter, SSC further removed from the ship the remaining damaged containers in accordance with LOF terms. The emergency response to the M/V CCNI RIMAC once again proved Shanghai Salvage Company to be the “Iron Army At Sea”, the one who plays a vital role at a crucial time.

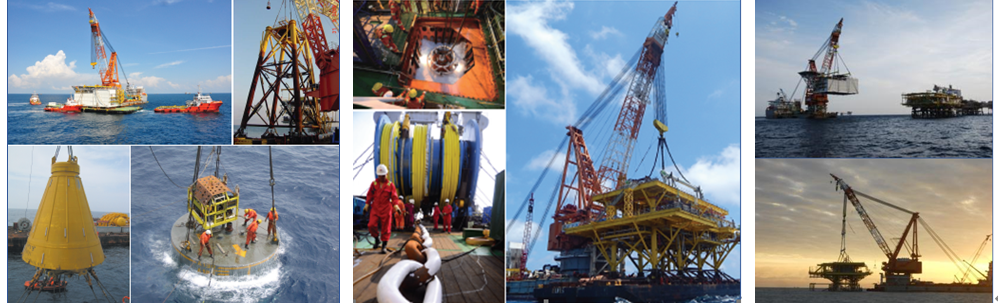

Offshore Construction (Oil &Gas/Offshore Wind/Decommissioning)

Offshore Oil & Gas

COES brings and applies decades of accumulated experience from offshore engineering and project management to the planning and execution activities for each of our offshore installation projects undertaken for our clients. Quality and success of each project ensured by an experienced team of engineering supervisors, discipline engineers, technical specialists, DP masters, diving superintendents and other operational and support staff;

Thanks to a world-class fleet, COES is operating for a wide range of offshore installation activities: underwater projects, port engineering, topsides and modules installation, jacket lifting and installation, deep diving and ROV services, riser and SPM installation, offshore pile driving and underwater welding, underwater inspection, repair and maintenance etc.

There are many examples of successful heavy lifts at sea undertaken by Shanghai Salvage / COES fleet which can be showcased - such as those of the 3,000t lifting capacity crane vessel "Wei Li". This vessel has left global footprints in Southeast Asia, the Indian Ocean, and the Gulf of Mexico, the North Sea of Europe, the Persian Gulf and many other waters, especially in the Gulf of Mexico, where it succeeded in lifting and installing the 2,900t jacket and in the Persian Gulf where it completed 2,441 tons of upper block lifting in full DP mode. Such successes have left a deep long lasting positive impression with many of the company’s international clients with excellent feedback having been solicited from them demonstrating an enviable track record.

Certain of the company’s assets also have 500m water depth installation capability, including spool piece, subsea manifold, riser, single point mooring system installation, submarine cable laying, tubing maintenance and underwater immersed tunnel construction.

Offshore Wind Installation

COES continues to invest in modern, diverse and world class assets. In particular, we have developed and successfully brought to market a range of 'state of the art' new construction engineering heavy lift and transportation vessels which will be ideally placed going forward to support the emerging global offshore renewable energy sector. Our capabilities extend to include acting as a modern tier 1 contractor to offer an 'end to end' solution for the transportation and installation of offshore wind structures (both fixed and floating) and also array cabling for the renewable energy developers. COES has in place cooperation arrangements with collection and marshalling ports and noise abatement third parties worldwide and is fully able to manage all the necessary sub contract interfaces to bring simplicity and added benefit to its clients.

Decommissioning

Due to similarity between offshore structure decommissioning and wreck removal, COES could transfer its superb existing skills and assets to decommissioning works. COES can provide 'End to End' solutions to our clients and covering all work scope of dismantling, transportation, removal and recycling of offshore structures and subsea infrastructure.

Ocean towing is one of the main businesses . As from 1970’s, COES started its international towage business. In 1998, COES associated with Svitzer Ocean Towage (ex “SmitWijs”), world- famous towage contractor, to establish Global Towage Alliance, to provide large- floating unit ocean towage such as FPSO and drilling rig, etc…

Our international track records have now spread to more than 100 nations, thanks to a powerful towage fleet including 5 ocean-going tugs with more than 160 tons bollard pull.All our ocean-going tugs meet international qualifications and obtained relevant certifications such as ISO9000, DOC, SMC and ISPS.

The company has successfully towed 300,000t class FPSOs: P67, P69, P70 and other super large offshore floating storage tankers exceptionally long distances, as well conducting successful tows for large drilling platforms, floating docks, semi-submersible pipe-laying vessels and barges which demonstrates the company’s world leading ocean towing capability and capacity.

Through our subsidiary Shenzhen Huawei Offshore Transport CO Ltd founded in 1983, a company specialized in offshore oil field services, COES provides AHTS and PSV dedicated to oil field supporting, offshore oil lifting operation services, anchor handling services and offshore construction supporting services.

Since its inception, Huawei has become one of the leading company and contractor with great competitive strength in domestic field supporting industry, and has established a complete Quality and Safety Management system in accordance with international standards. Huawei is committed to deliver top-quality and safe services that provides the foundation for our company’s sustainable development.

Saturation diving is one of the core business in COES and a new economic growth point. In December 2006, 200m saturation diving methodology was adopted for repairing the single point riser of Panyu oilfield, which is a breakthrough in the commercial application of saturation diving technology in China. In 2009, the worldwide advanced 300m saturation diving system was installed on the newly built DSV Shen Qian Hao, which lead our deep diving operation capacity to the international first-class level. Over the years, saturation diving operations have been successfully carried out by COES in Panyu, Xijiang, Wenchang, Yacheng and Huizhou oilfields in the South China Sea. In January 2014, the first saturation diving operation deeper than 300m in China was completed by COES at the South China Sea, and the maximum depth reached 313.5m.

COES has two largest diving equipment factories in China, manufacturing hyperbaric oxygen chamber, decompression chamber, diving bell, diving suit and diving equipment. Our factories has developed new diving equipment, bulk tanks1200 buoyancy pontoons and emergency disaster prevention products. All these products have been certified by China Classification Society, Bureau Veritas or det Norske Veritas and obtained corresponding certificates.

COES also participated in bridge construction, tunnel construction and other types of construction projects. Such as successfully participated in and completed the installation of Donghai Bridge. In Ningbo Changhong tunnel project, our company has won the honorary title of "the fourth Zhan Tianyou Civil Engineering Award".

Home

Home